3D printing is superior—till your software program turns it right into a nightmare.

I discovered this the arduous means whereas testing among the finest 3D printing software program. One second, I used to be excited to slice a mannequin; the subsequent, I used to be trapped in a complicated mess of settings, error messages, and prints that seemed nothing like they need to.

Now, I’m not a 3D printing knowledgeable. I don’t spend my days obsessing over layer heights or tweaking temperature settings (although I now have a newfound respect for many who do). However what I do know is software program—what makes it user-friendly, what options really matter, and what’s pointless fluff.

So, I did what any curious individual would do: I examined, explored, and in contrast among the hottest 3D printing instruments to see which of them stand out.

I checked out every part—from beginner-friendly slicers to superior modeling instruments—specializing in usability, options, and general printing success. Some software program made the method easy; others felt like they have been actively attempting to spoil my day. And now, after loads of hands-on testing, I’m able to share my findings.

Whether or not you’re a complete beginner, a severe maker, or someplace in between, listed here are my high picks for the very best 3D printing software program options which are value your time.

7 finest 3D printing software program for 2025: My favorites

- Onshape for cloud-based CAD, real-time collaboration, and design information administration. ($1500/person/12 months)

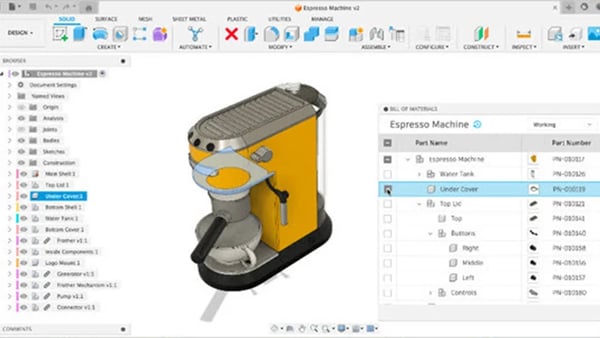

- Autodesk Fusion for built-in 3D design options, manufacturing, and simulation. ($680/person/12 months)

- Siemens NX for complete suite that helps superior 3D design and engineering. ($614.25/month)

- Stable Edge for distinctive synchronous know-how and versatile design workflows. ($261/month)

- SOLIDWORKS for easy-to-use 3D design, simulation, and information administration. ($2,820/12 months)

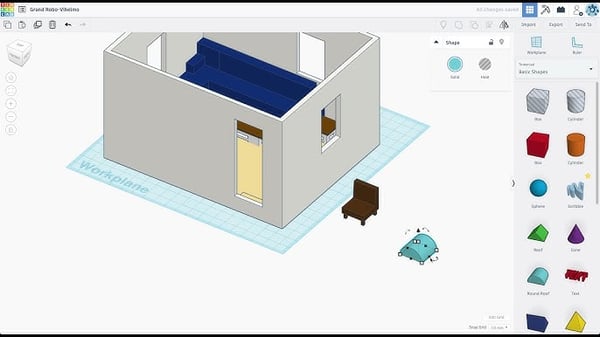

- Tinkercad for beginner-friendly, easy, and accessible on-line 3D design instruments. (free)

- Ultimaker Cura for dependable 3D printing mannequin preparation. (free)

*These 3D printing software program options are top-rated of their class, in response to G2 Grid Experiences. I’ve additionally added their month-to-month/annual pricing to make comparisons simpler for you.

7 finest 3D printing software program I really like utilizing

3D printing seems like magic. You begin with a digital design, press a couple of buttons, and bam—your thought turns into a bodily object. However as I rapidly discovered, it’s not so simple as dragging a file into your printer and hoping for the very best.

At its core, 3D printing software program is the intermediary between your design and your printer. Some applications allow you to create and edit 3D fashions from scratch, whereas others concentrate on slicing—mainly, breaking your mannequin down into printable layers and producing the correct directions to your printer. After which there are all-in-one options that do a mixture of each.

Since I don’t design intricate 3D fashions for a dwelling, I centered on how effectively these instruments steadiness energy and value. I needed to see which of them make the method straightforward for novices, which of them give execs the superior instruments they crave, and which of them make issues tougher than they must be.

How did I discover and consider the very best 3D printing software program?

I needed to grasp what makes 3D printing software program nice (or irritating), so I went past surface-level impressions and began investigating actual person experiences.

I seemed into G2 grid reviews, which gave me a transparent view of how totally different 3D printing software program ranked by way of usability, options, and buyer satisfaction. G2’s insights helped me perceive which applications have been really delivering on their guarantees and which of them had constant ache factors. I additionally used AI to research a whole lot of person opinions for various options to grasp person sentiment past my testing.

This helped me slender down a shortlist of essentially the most promising and talked-about 3D printing software program on G2 that I examined in opposition to a set of things.

What makes the very best 3D printing software program value utilizing? My standards

3D printing ought to be enjoyable and rewarding, not a multitude of failed prints and complicated settings. I centered on a couple of key standards throughout my analysis to ensure I used to be recommending the very best instruments for several types of customers.

- Newbie-friendly: I needed to check how straightforward it was to start out with every resolution. Might I load a mannequin, slice it, and generate a print file with out digging via a tutorial? A very good interface ought to make the method intuitive, not like a puzzle. Some software program struck an ideal steadiness between simplicity and customization, whereas others buried vital settings behind layers of menus. I additionally checked out how straightforward it was to navigate, manipulate objects, and export recordsdata with out getting misplaced in countless toolbars. A steep studying curve isn’t at all times dangerous, however a complicated interface is a dealbreaker.

- Slicing efficiency: Slicing is the place your 3D mannequin will get transformed into printable layers, and dangerous slicing can spoil a print earlier than it even begins. I examined how effectively every instrument optimized help buildings, infill density, and layer heights. Among the finest 3d printing software program do an ideal job balancing pace and precision, whereas others require extra tweaking to keep away from wasted filament and failed prints. I additionally checked for pace of slicing, help technology, and infill effectivity.

- Customization and management: For extra skilled customers, customization is vital. I checked if I may tweak layer peak, wall thickness, retraction settings, and print pace. A very good 3D printing instrument ought to permit granular management with out making it too troublesome to navigate. I additionally examined variable layer peak, retraction settings, and different optimizations to enhance print high quality.

- Stability and compatibility: Some applications wrestle with massive or advanced fashions, and a instrument that crashes mid-way is extremely annoying. I examined how effectively every program dealt with high-detail STL recordsdata and multi-part assemblies with out freezing or failing. I additionally checked out compatibility with totally different 3D printers and file codecs. Some software program is locked to particular manufacturers, whereas others work with virtually any machine. An amazing 3d printing resolution ought to help STL, OBJ, and 3MF codecs. It also needs to help a number of printer manufacturers and firmware varieties.

- Print success charge: On the finish of the day, the very best software program produces profitable prints with minimal troubleshooting. I ran take a look at prints sliced by every program and checked for print accuracy, first-layer adhesion, and general print high quality. Some instruments wanted lots of guide tweaking to get a very good print, whereas others had nice default profiles that labored proper out of the field.

By testing usability, slicing efficiency, superior options, stability, and print success charge, I may separate the seven finest 3d printing software program from those that make issues tougher than they must be.

The checklist beneath comprises real person opinions from G2’s finest 3D printing software program class web page. To be included on this class, an answer should:

- Translate 3D fashions into printable directions for 3D printers

- Restore and edit STL, 3MF, or OBJ recordsdata

*This information was pulled from G2 in 2025. Some opinions might have been edited for readability.

1. Onshape

Onshape is a browser-based computer-aided design (CAD) platform that replaces the old-school, clunky software program mannequin with a totally cloud-powered expertise. Not like conventional CAD applications that require hefty installations and fixed file administration, Onshape runs fully in your net browser, which means I may entry my tasks from actually wherever—together with my telephone (which felt bizarre however surprisingly labored).

I needed to see how effectively Onshape matches right into a 3D printing workflow, so I ran it via a couple of exams. First, I loaded up some pattern designs and tried tweaking them in Onshape’s parametric modeling system. When you’re used to freeform mesh-based design (like Tinkercad or Blender), Onshape’s precision-based method may take some getting used to. Every little thing is constructed with constraints and relationships, which means you outline issues with actual measurements as a substitute of simply eyeballing shapes. It’s extremely highly effective—but in addition not precisely pleasant to informal customers.

One other characteristic that stood out was real-time collaboration. I examined this by opening the identical undertaking on my laptop computer and one other machine on the similar time. Edits have been up to date immediately, which makes Onshape a robust selection for team-based design. The built-in model management was additionally helpful—I may return to earlier variations with out manually saving totally different file names.

Nonetheless, Onshape shouldn’t be a slicer, so after creating or modifying a mannequin, you continue to have to export it to organize it for printing. The export course of is easy, and it helps STL and OBJ codecs, however I might have beloved some primary slicing instruments built-in to preview how a design would print earlier than switching software program.

Then there’s the free model—it’s nice that they provide one, nevertheless it comes with a giant catch: you may solely create public paperwork. Which means for those who’re engaged on proprietary designs or simply don’t need your experimental creations out within the wild, you’ll want a paid plan.

Onshape is finest for customers who want structured, precision modeling and collaboration instruments. When you design mechanical elements or want actual management over your fashions, it does that effectively. However for those who’re in search of an all-in-one instrument that features slicing and print prep, you’ll want one thing else to finish the workflow.

What I like about Onshape:

- I didn’t have to put in or obtain something. As somebody who hates software program bloat, I beloved this. Onshape felt simply as responsive as conventional software program with out the standard setup problem.

- I opened Onshape on my telephone simply to see if it labored, and surprisingly, I may make small edits (although I wouldn’t advocate doing main modeling work on a tiny display screen).

What G2 customers like about Onshape:

“Onshape CAD instrument is net primarily based instrument in order that it may be accessed from Cellular platform too. Onshape has good tutorials to assist the brand new learners. Buyer help can also be very good. DXF, STP, IGS, and many others., and well-known 3D platform fashions may also be simply built-in. In meeting, we are able to arrest aside with a single mounted mate. It’s a good implementation in CAD instruments. “S” shortcut is sweet for frequent use of characteristic choice.”

– Onshape Overview, Senthil N.

What I dislike about Onshape:

- Since Onshape is browser-based, there’s no offline mode. I attempted utilizing it throughout a spotty Wi-Fi second, and it doesn’t work in any respect with out an web connection.

- It’s not a slicer. I needed to export my fashions to a different program to organize them for printing, which added an additional step to my workflow.

What G2 customers dislike about Onshape:

“The principle draw back is the pace of Onshape. Since it’s within the cloud, the efficiency shouldn’t be as snappy as that of a neighborhood CAD system like Solidworks. That is primarily seen in assemblies. The second draw back is a part of its characteristic: Paperwork. Paperwork can get slowed down in a short time with half studios and assemblies and derived elements.”

– Onshape Overview, Sebastian S.

2. Autodesk Fusion

Autodesk Fusion is likely one of the most generally used CAD instruments in engineering, product design, and manufacturing, however I needed to see how effectively it really works particularly for 3D printing. Because it’s a hybrid of parametric, direct, and sculpting modeling, it affords extra flexibility than software program that solely focuses on structured, mechanical design. Not like less complicated applications, it additionally has simulation, stress testing, and meeting instruments, making it helpful for designing practical elements reasonably than simply ornamental prints.

One of many first issues I examined was Autodesk Fusion’s built-in slicer since not many CAD instruments supply that. It’s a part of the Manufacturing workspace, and it helps you to generate G-code instantly inside Fusion as a substitute of exporting your file into one other program. This labored effectively for easy prints, however I observed it lacks the depth of management you’d get in among the different 3d printing instruments.

For instance, whilst you can set infill patterns and layer heights, it doesn’t have as many superior help technology choices. When you’re engaged on prints that require intricate help buildings or extremely optimized slicing methods, you’ll most likely nonetheless wish to use a devoted slicer.

One other characteristic I examined was Autodesk Fusion’s mesh restore instruments. When you’ve ever tried printing a mannequin solely to understand it’s filled with non-manifold geometry or holes, you understand how annoying that may be. Fusion’s restore instrument rapidly recognized damaged STL recordsdata and advised automated fixes, which saved me from needing third-party instruments like Netfabb. I ran a couple of drawback STLs via it, and normally, the restore course of labored effectively sufficient that Cura accepted the recordsdata with no points. It’s not good—some advanced recordsdata wanted guide intervention—however for fast fixes, it was an enormous time-saver.

One other space the place Autodesk Fusion stood out was its potential to change between parametric and freeform modeling. Parametric modeling is nice for exact, engineering-style elements, however you may change to the sculpting workspace for extra natural or creative prints, which helps you to push and pull geometry extra fluidly. This gave me extra flexibility than software program that locks you right into a single modeling method.

Now, let’s speak about the place Autodesk Fusion didn’t work as effectively for 3D printing. First, the UI is barely dense. This isn’t essentially a nasty factor for those who want all of the superior instruments, however for somebody wanting solely to switch a mannequin and ship it to a printer, it will possibly really feel like overkill. Even easy changes require navigating via a number of menus, and a few generally used features felt buried below pointless steps.

One other subject I bumped into was Autodesk Fusion’s dealing with of high-poly STL recordsdata. After I imported massive, detailed fashions, the software program slowed down noticeably, even on a comparatively highly effective system. It appears optimized for native Autodesk Fusion recordsdata reasonably than heavy STLs. This isn’t a dealbreaker, however for those who incessantly work with scanned fashions or high-detail sculpted designs, count on some efficiency slowdowns.

What I like about Autodesk Fusion:

- The built-in stress testing and simulation instruments aren’t one thing each 3D printing workflow wants, however I preferred with the ability to analyze how the half would behave below load earlier than printing, whether or not for practical prints or mechanical elements.

- Cloud-based storage was nice for simple entry throughout gadgets. I may pull saved recordsdata on one other machine with none additional steps or worrying about guide file transfers.

What G2 customers like about Autodesk Fusion:

“The quantity of options out there. My favourite characteristic is the sketch operate. It really works flawlessly when going from sketch to design. Additionally, the flexibility to import a canvas and calibrate it to virtually good accuracy is superior. I can recreate a number of objects for 3d printing and alter the design to what I want.”

– Autodesk Fusion Overview, Aaron H.

What I dislike about Autodesk Fusion:

- I discovered myself clicking via a number of menus simply to make small adjustments. When you’re in search of a easy technique to tweak and print fashions, this software program might get barely advanced.

- The built-in slicing instruments lack help construction customization, infill sample management, and different fine-tuning choices. I discovered it helpful for fast prints however not a full slicing resolution.

What G2 customers dislike about Autodesk Fusion:

“Two facets of Autodesk Fusion 360 that I discover much less favorable are its dependency on an web connection and its CAD file compatibility. Whereas cloud-based software program usually affords vital benefits, options like real-time collaboration and automated saving will be difficult in areas with restricted connectivity. Moreover, regardless of supporting many file codecs, the conversion of recordsdata throughout export is usually restricted, ensuing within the lack of particulars or geometries when importing to different software program.”

– Autodesk Fusion Overview, Juan M.

Nice prints begin with nice designs, and understanding traits in graphic design may also help you create extra visually interesting and practical 3D fashions. Take a look at the newest graphic design statistics now.

3. Siemens NX

Siemens NX affords an all-in-one engineering platform for aerospace, automotive, and high-end manufacturing. It’s strictly constructed for professionals who want precision modeling, superior simulation, and direct management over additive manufacturing (AM) processes. What actually units it aside is its potential to deal with advanced, multi-material, and industrial-scale 3D printing workflows, which is one thing most CAD applications don’t even try.

The very first thing I examined was NX’s built-in help for steel 3D printing. Whereas most 3d printing software program focuses on FDM printing, NX contains devoted instruments for powder mattress fusion (PBF), direct power deposition (DED), and SLA processes. I experimented with PBF-specific help buildings, that are important for steel printing. NX robotically optimized help buildings primarily based on thermal distortion and stress distribution. This stage of precision is a large benefit for industries working with high-cost supplies like titanium or Inconel, however for on a regular basis FDM printing, it’s pointless.

Subsequent, I explored Siemens NX’s simulation-driven print preparation. Most slicing software program will generate a toolpath, however NX analyzes your entire construct course of earlier than printing begins. I loaded a posh aerospace bracket mannequin and ran an evaluation that predicted areas of potential warping and distortion attributable to warmth buildup. That is means past what conventional 3d printing software program and slicers can do, and it’s vital for steel printing or massive industrial prints the place failure means hundreds of {dollars} in wasted materials.

One other standout characteristic was NX’s hybrid manufacturing instruments, which permit customers to mix subtractive and additive manufacturing in a single workflow. I examined a state of affairs the place I printed a steel half with inside lattice buildings after which simulated post-processing with CNC machining to refine the outer surfaces. That is one thing utterly distinctive to NX, and it’s ultimate for industries the place 3D printing is only one step in a bigger manufacturing pipeline.

Now, coming to what wasn’t nice. First, the software program was overwhelming for me to make use of. Even with CAD expertise, I discovered myself spending an excessive amount of time trying to find instruments. It’s a full engineering suite, not only a 3D printing instrument, so it comes with layers of complexity that aren’t obligatory for most individuals’s printing wants.

One other drawback with Siemens NX is that it’s constructed for enterprise customers. Not like Fusion 360, which has a free model, or Onshape, which runs in a browser, NX requires severe licensing prices. When you’re a hobbyist or perhaps a small enterprise, it’s not a viable possibility until you’re employed in high-precision industries.

What I like about Siemens NX:

- Siemens NX affords hybrid manufacturing instruments. I examined a workflow the place I 3D printed a posh half and simulated post-processing with CNC machining—one thing no different software program may do.

- It affords the best-in-class steel 3D printing help. I may generate PBF-specific help buildings optimized for warmth and stress discount.

What G2 customers like about Siemens NX:

“NX is a complete, all-in-one instrument to help my 3d printing workflow. This highly effective program has every part I have to design and produce elements rapidly and effectively. With its intuitive interface, superior 3D modeling capabilities, and built-in simulation instruments, it is no surprise that this software program has turn out to be my all-time favourite. Siemens NX helps me streamline the additive manufacturing course of. Its options allow straightforward creation of advanced geometries of any dimension or form with precision and accuracy. It additionally contains automated simulations that may analyze materials properties in addition to design and machine compatibility points earlier than any half is produced.”

– Siemens NX Overview, Areeb I.

What I dislike about Siemens NX:

- I didn’t discover this instrument ultimate for desktop FDM printing. Whereas it excels in steel and resin printing, NX lacks fine-tuned FDM-specific slicing controls, so it’s not a sensible selection for small-scale customers.

- The instrument will be difficult to grasp. Because it’s a full engineering suite, not only a 3D printing instrument, it takes vital time to get used to, particularly for those who don’t want all its options.

What G2 customers dislike about Siemens NX:

“Essentially the most disliked factor about NX CAD is that it isn’t that user-friendly after we discuss within the context of recent customers (instructional functions) in comparison with the opposite software program, and getting the academic license is one other drawback that’s fairly simply out there for Autodesk merchandise. The reason being that almost all Autodesk merchandise are most popular in India. Yet one more factor that may be thought of is the shopper care help that’s lagging within the case of the entire Siemens group, which is sort of higher than Dassault Methods.”

– Siemens NX Overview, Anjan M.

Now that you simply’ve discovered the correct 3D printing software program, why cease at static fashions? Take a look at our checklist of the finest animation software program and begin making your creations transfer.

4. Stable Edge

Stable Edge is Siemens’ extra accessible CAD resolution, positioned between beginner-friendly software program and full-blown engineering suites like NX. I needed to see how effectively it really works for 3D printing workflows, particularly because it contains direct modeling, parametric design, and a devoted 3D printing surroundings.

Not like Onshape or Fusion 360, which concentrate on cloud-based collaboration, Stable Edge is a neighborhood set up with an emphasis on conventional engineering workflows.

One of many first issues I examined was Stable Edge’s convergent modeling characteristic. This can be a distinctive hybrid method that permits you to work with mesh-based STL recordsdata alongside parametric CAD fashions. When you’ve ever tried modifying an STL in a typical CAD program, it’s a nightmare—most CAD instruments deal with STLs as “dumb” geometry, which means you may’t simply make exact edits.

With convergent modeling, I may mix mesh-based designs with exact parametric options with out manually changing them. This made repairing, modifying, and getting ready 3D scan information a lot simpler.

Subsequent, I explored the devoted 3D printing surroundings, which streamlines the method of getting ready fashions for additive manufacturing. Not like most CAD software program, Stable Edge really helps you to ship recordsdata on to a 3D printer without having a separate slicer. I examined this with an STL file, and it supplied built-in instruments for checking wall thickness, figuring out unsupported areas, and previewing layer heights. It’s not as detailed as another options, however for fast prints, it saves time by eliminating the necessity for a separate slicing step.

One other standout characteristic was reverse engineering help. Stable Edge contains automated mesh cleanup instruments that assist flip messy scans into clear, printable fashions. I examined this by importing a low-quality 3D scan and utilizing Stable Edge’s smoothing and edge-repair instruments. Whereas it improved the mannequin, it didn’t totally repair each subject, and I nonetheless needed to modify areas with dangerous topology manually. The automation is useful, nevertheless it gained’t change the necessity for guide cleanup in lots of circumstances.

Then there’s the interface, which was one in every of my largest frustrations. Stable Edge packs an enormous variety of instruments into the UI, which makes it really feel cluttered and overwhelming. Even after adjusting the workspace format, I nonetheless needed to click on via a number of menus for widespread features. The ribbon-based design feels outdated in comparison with extra trendy, streamlined CAD instruments.

One different surprising subject I bumped into was import/export limitations. Whereas Stable Edge helps many CAD file varieties, it struggled with bigger, high-polygon STLs. I examined an in depth natural mesh file, and whereas it was technically imported, it grew to become gradual and unresponsive once I tried making edits. This means that Stable Edge remains to be higher suited to structured, CAD-based fashions reasonably than extraordinarily detailed meshes, which might be problematic for those who’re working with 3D scans or sculpted designs from Blender.

What I like about Stable Edge:

- Direct modeling supplied flexibility for modifying present elements. Not like totally parametric CAD techniques, I may rapidly tweak imported fashions with out redefining constraints, which made it sooner for iterative design.

- Reverse engineering instruments helped with 3D scans. I imported a messy scan, and Stable Edge’s restore instruments improved it—although some guide cleanup was nonetheless required.

What G2 customers like about Stable Edge:

“Essentially the most useful factor about Stable Edge is the flexibility to simply map out your ideas and concepts onto the display screen with the instruments which are out there, be it 3D or 2D. The truth that the restricted model is free is what additional helped me to proceed utilizing this product for my private work.”

– Stable Edge Overview, Shayaan R.

What I dislike about Stable Edge:

- 3D printing instruments really feel half-finished. I discovered the printability checks good however the slicing options have been too restricted—I couldn’t modify retraction, infill density, or superior help settings.

- Some 3D printing options aren’t out there within the primary model, which implies particular person customers like myself might not get essentially the most out of this instrument with out paying for premium tiers.

What G2 customers dislike about Stable Edge:

“There are some things that I do not like. Typically, I want to make use of a 3D dxf file, however I can not import it in Stable Edge as a result of it does not help it. One other comparable factor is importing .3mf (a well-liked file format for 3D printing) file that’s not impartable in SE.”

– Stable Edge Overview, Imre S.

5. SOLIDWORKS

SOLIDWORKS is likely one of the most generally used CAD applications in engineering and product design, however I needed to see how effectively it handles 3D printing particularly. Not like Fusion 360, which is extra cloud-focused, or Siemens NX, which is constructed for full industrial workflows, SOLIDWORKS sits someplace in between—it’s native software program with sturdy parametric design instruments, simulation options, and a few useful 3D printing integrations.

One factor that instantly stood out to me was how customizable the workflow is for 3D printing—however that’s each a very good and a nasty factor. Not like software program that robotically guides you thru a 3D printing course of, SOLIDWORKS requires some setup to get every part working easily. As soon as I configured it accurately, although, it supplied a powerful stage of management over mannequin preparation, slicing previews, and print validation.

I examined the Print3D instrument, which helps you to test your mannequin for printability, modify orientation, and even generate a preview of the slicing layers. It was helpful for validating a design earlier than exporting to an exterior 3D printing software program. The automated error detection was particularly useful—it flagged skinny partitions, overhangs, and areas that will require additional help earlier than I even exported the file.

One other characteristic I examined was SOLIDWORKS’ potential to generate honeycomb and gyroid infill buildings instantly contained in the mannequin. As an alternative of counting on a slicer to create infill patterns, I may design light-weight inside buildings as precise geometry. This was significantly helpful for engineering elements that wanted particular strength-to-weight ratios. Most 3D printing software program solely helps you to modify infill proportion, however in SOLIDWORKS, I had full management over the construction itself.

The perfect a part of SOLIDWORKS for 3D printing is how effectively it integrates with superior simulation instruments. I ran thermal and stress exams on a mannequin earlier than printing, and the software program helped establish weak factors that would fail in the course of the print or in real-world use. That is massively useful for practical elements, particularly for industrial purposes.

That being mentioned, SOLIDWORKS shouldn’t be the best program to work with for 3D printing. The file export course of was somewhat clunky, requiring additional steps simply to avoid wasting STLs with the correct decision. I additionally discovered that working with advanced STL recordsdata was irritating—in contrast to Stable Edge, which helps you to modify STLs instantly, SOLIDWORKS doesn’t deal with mesh-based fashions effectively. When you’re working with scanned elements or sculpted designs from Blender, count on some challenges.

One other draw back? The licensing mannequin. SOLIDWORKS doesn’t have a free model, and the price is important. When you solely want CAD instruments for 3D printing, it’s arduous to justify the value until you’re already utilizing it for different engineering work.

What I like about SOLIDWORKS:

- The Print3D instrument gave me a stable preview earlier than exporting. I preferred with the ability to test overhangs, wall thickness, and slicing layers inside SOLIDWORKS earlier than sending my file to a slicer.

- Constructed-in infill design choices have been extra superior than typical slicers. As an alternative of simply adjusting infill percentages, I may create structured, optimized inside lattices instantly within the CAD mannequin.

What G2 customers like about SOLIDWORKS:

“Solidworks has a really intuitive interface for half and meeting design. It has energy parametric modeling options that allow extra superior meeting/half help. The software program additionally does a very good job of exporting to numerous file varieties whether or not it’s .STEP for CAD sharing or .STL for 3D printing.”

– SOLIDWORKS Overview, Josh L.

What I dislike about SOLIDWORKS:

- The export course of for 3D printing was extra difficult than obligatory. I needed to manually modify STL settings to get the correct decision.

- Not like software program that guides you thru slicing and preparation, SOLIDWORKS expects you to configure your individual course of. That is nice for superior customers however will be irritating for novices like me.

What G2 customers dislike about SOLIDWORKS:

“The one draw back I’ve discovered is the occasional slowdown and typically crash. Often, that is extra of a pc/graphics card subject or dangerous type in creating assemblies which are too massive, however it’s a problem typically.”

– SOLIDWORKS Overview, Ryan S.

6. Tinkercad

Tinkercad might be essentially the most beginner-friendly 3D printing software program on the market, and I needed to see if it was only for children and hobbyists or if it may deal with extra severe printing wants. Not like the opposite instruments I examined, which concentrate on parametric modeling, industrial workflows, or superior simulation, Tinkercad is all about accessibility.

It’s a web-based program that permits you to drag, drop, and mix shapes to create 3D fashions, making it good for somebody who has by no means labored with CAD earlier than.

The very first thing I observed was how briskly I may begin designing. There was no software program to put in and no difficult setup—I simply opened my browser, created an account, and inside 5 minutes, I used to be already making primary shapes and mixing them into printable objects. If different CAD software program makes you are feeling such as you want an engineering diploma, Tinkercad is the other.

I examined its pre-made form library, which incorporates geometric solids, textual content, and even primary mechanical elements like gears. This made designing easy objects like keychains, nameplates, and enclosures extremely straightforward. Not like software program that requires sketching constraints or adjusting exact parametric values, Tinkercad is only visible—you simply drag objects, resize them, and stack them collectively. I may see why faculties and maker areas use it a lot—it removes all of the technical boundaries to entry.

One characteristic that shocked me was the block-based coding instrument, which helps you to generate shapes utilizing code as a substitute of manually putting them. I performed round with it and located that it was a very good introduction to algorithmic design, nevertheless it lacked the depth of parametric modeling instruments like SOLIDWORKS or Fusion 360. Nonetheless, for instructing children or novices about procedural modeling, it’s a pleasant addition.

Nonetheless, Tinkercad has main limitations with regards to extra superior 3D printing wants. First, there aren’t any precision instruments—you may’t outline actual constraints, alignments, or tolerances like you may in skilled CAD software program. When you’re designing practical elements that want to suit along with tight tolerances, you’ll rapidly hit a wall.

One other large disadvantage is file dealing with. Since Tinkercad runs in a browser, it struggles with massive or advanced fashions. I imported a high-poly STL simply to check it, and the system grew to become sluggish and unresponsive. This makes it a poor selection if you should modify present 3D scans or sculpted designs.

What I like about Tinkercad:

- Pre-made form library makes designing enjoyable and easy. I constructed 3D fashions simply by combining present shapes—there was no have to manually create advanced geometry.

- The quickest and best technique to begin 3D modeling. I’ve examined lots of CAD software program, and none of them let me go from zero to designing as rapidly as Tinkercad. I didn’t should study instructions, arrange a workspace, and even watch tutorials.

What G2 customers like about Tinkercad:

“I by chance found TinkerCAD on a 3D printing discussion board. I used to be instantly blown away by how straightforward it was to arrange the account and get began. It shops designs on the cloud, which will be accessed from wherever. The instruments are easy and intuitive to entry. You’ll be able to even import recordsdata from different software program and incorporate them into your individual design. Particularly for normal 3D printing people, it is an on a regular basis instrument that can not be seemed over; it is actually like making LEGOs. It is enjoyable to make use of and is practical. When you get caught, there’s additionally a really good discussion board with a really good group.”

– Tinkercad Overview, Anubhav M.

What I dislike about Tinkercad:

- Can’t deal with high-poly fashions or advanced designs. I imported an in depth 3D scan with a excessive polygon depend, and Tinkercad lagged. If you should modify sculpted fashions or scanned objects, this software program merely isn’t constructed for that.

- No precision management for mechanical elements. I attempted designing a snap-fit case, and there was no technique to outline actual tolerances. With out the flexibility to set constraints, align options exactly, or measure clearances precisely, practical elements are troublesome to create.

What G2 customers dislike about Tinkercad:

“Though it is vitally useful and simple to make use of for novices and start-ups. It may use extra superior options sooner or later which are presently lacking to rival extra design-oriented skilled 3D software program.”

– Tinkercad Overview, Omar M.

7. Ultimaker Cura

Ultimaker Cura is likely one of the most generally used 3D printing software program choices, and I needed to see if it really deserves its popularity. Cura isn’t about designing fashions—it’s about getting ready them for printing. It’s a devoted slicing software program that interprets your 3D mannequin right into a set of directions to your printer, and it’s utterly free.

The very first thing I examined was how Cura handles mannequin preparation. I loaded up a couple of STLs and was impressed with how rapidly it processed them, even on advanced, high-detail fashions. The UI is clear and simple to navigate, and I didn’t should dig via countless menus to seek out the settings I wanted. Cura robotically detected my printer’s specs, which saved me from manually inputting construct quantity, nozzle dimension, and different particulars.

Subsequent, I experimented with Cura’s intensive print settings. There are over 400 adjustable parameters, masking every part from layer peak and print pace to cooling fan speeds and acceleration settings. I began with Cura’s default profiles, that are optimized for varied Ultimaker printers, they usually labored surprisingly effectively. However since I don’t at all times use Ultimaker machines, I additionally personalized my very own profiles and located that Cura affords extra fine-tuning management than most free 3D printing software program.

Considered one of Cura’s standout options is tree helps—a setting that generates natural, branching help buildings as a substitute of inflexible pillars. I examined this on a posh overhanging mannequin, and the tree helps have been a lot simpler to take away than customary helps, plus they used much less filament. That is one thing I haven’t seen in lots of different slicers, and it’s extremely helpful for delicate prints or fashions with intricate overhangs.

One other characteristic I preferred was Cura’s post-processing scripts. This lets you add customized G-code instructions at totally different phases of a print, which is nice if you wish to pause for inserting magnets, change colours mid-print, and even set off a customized motion in your printer. I arrange a easy filament swap at layer 50, and it labored and not using a hitch.

Nonetheless, one of many largest frustrations I had with Cura was the print time estimation. The estimated print occasions Cura gave me have been usually means off—typically by hours. When you depend on Cura’s estimates to plan your prints, you is perhaps in for a shock when your print takes for much longer than anticipated.

One other subject I bumped into was Cura’s useful resource utilization. It’s a reasonably demanding software program, and once I was slicing a high-poly mannequin with tremendous element settings, my pc slowed to a crawl. It’s not an enormous deal when you have a high-performance PC, however on older or lower-end machines, count on some lag when processing massive recordsdata.

Lastly, Cura works finest with Ultimaker printers, which isn’t stunning on condition that it’s developed by Ultimaker. Whereas it does help third-party printers, I needed to manually tweak settings to get Cura working easily with non-Ultimaker machines. Some presets have been incomplete or outdated, which means I needed to spend additional time fine-tuning settings for customized printers.

What I like about Ultimaker Cura:

- Cura’s default profiles are well-optimized. After I used Cura’s built-in settings for widespread filaments, prints got here out nice without having lots of tweaking. The built-in presets work particularly effectively for Ultimaker printers.

- Cura additionally affords intensive customization choices. With over 400 settings, I had full management over print pace, cooling, infill density, and even acceleration settings, making it some of the customizable free slicers on the market.

What G2 customers like about Ultimaker Cura:

“Cura is extremely intuitive, which is saying one thing since 3D printing has a ton of variables to cope with. Nonetheless, they’re all specified by a means that simply is smart. Better of all, I’ve by no means had a single “software program subject” via any of my a whole lot of prints. Something that has gone fallacious has been on me attributable to a configuration error, or one thing with the printer itself.”

– Ultimarker Cura Overview, Patrick M.

What I dislike about Ultimaker Cura:

- Print time estimates are sometimes inaccurate. On a number of prints, Cura underestimated the precise print time, typically by a number of hours. I needed to begin ignoring Cura’s estimates and use exterior instruments for higher accuracy.

- Cura can get resource-intensive on massive prints. When slicing a extremely detailed mannequin with tremendous layer settings, it slowed down considerably. When you’re utilizing an older or lower-end pc, count on some lag when slicing advanced fashions.

What G2 customers dislike about Ultimaker Cura:

“I can not level out any single issue that I disliked about Ultimaker Cura as a result of I’m nonetheless pretty new to 3D modeling and 3D printing. This can be a broadly used software program, so any difficulties will be solved by posting on varied boards to get suggestions on any subject.”

– Ultimarker Cura Overview, Shay D.

Comparability of the very best 3D printing software program

| Software program | G2 score | Free plan | Excellent for |

| Onshape | 4.7/5 | Sure | Engineers, product designers, and groups needing cloud-based collaboration. |

| Autodesk Fusion | 4.5/5 | Sure | Professionals and makers who want built-in CAD, simulation, and slicing instruments. |

| Siemens NX | 4.4/5 | No | Enterprise customers, aerospace, and automotive engineers needing high-precision modeling. |

| Stable Edge | 4.3/5 | Sure | Mechanical designers and professionals working with STLs and scanned elements. |

| SOLIDWORKS | 4.4/5 | No | Engineers and producers requiring parametric design and superior simulations. |

| Tinkercad | 4.5/5 | Sure | Newcomers, college students, and educators in search of an easy-to-use 3D design instrument. |

| Ultimaker Cura | 4.7/5 | Sure | 3D printing fanatics and professionals needing a dependable slicing instrument. |

Be aware: G2 Scores are primarily based on person opinions and are topic to vary.

Regularly requested questions on the very best 3D printing software program

Have extra questions? Discover extra solutions beneath.

Q. What’s the finest software program for 3D printing?

There’s no single “finest” software program—it relies on what you’re doing. When you’re in search of slicing software program, Ultimaker Cura is likely one of the most generally used choices, and it’s utterly free. For these designing mechanical or engineering-grade elements, Autodesk Fusion and SOLIDWORKS supply highly effective modeling instruments with exact management. Newcomers who simply wish to create easy, printable fashions will discover Tinkercad to be the best entry level. When you want one thing for industrial-scale tasks with high-end simulation instruments, Siemens NX is a top-tier selection.

Q. Can I take advantage of cellular or web-based software program for 3D printing?

In order for you a totally cloud-based CAD program, Onshape permits for modeling on any machine, together with tablets. Tinkercad runs fully in an online browser and works effectively for fast designs. Nonetheless, most slicing software program, together with Cura, must be put in on a desktop and doesn’t have cloud performance.

Q. What’s the distinction between CAD software program and 3D printing software program?

CAD software program is used to create and design 3D fashions, whereas 3D printing software program (usually referred to as slicing software program) is used to organize these fashions for printing. A CAD program helps you to design exact, practical elements. As soon as the design is full, slicing software program converts it into printable layers and generates G-code, which tells the printer find out how to construct the thing. Some software program integrates each CAD and slicing options, permitting you to design and put together prints in the identical surroundings.

Q. Which software program is finest for industrial or aerospace 3D printing?

For industrial and aerospace purposes, Siemens NX and Autodesk Fusion are high selections attributable to their superior simulation, topology optimization, and high-precision modeling instruments. SOLIDWORKS can also be broadly used for engineering-grade design and half validation. When you’re working with steel 3D printing, Siemens NX affords built-in additive manufacturing instruments to optimize prints for power and materials effectivity.

Q. What’s the very best 3D printing software program for Mac customers?

Most 3D printing software program is Home windows-first, however Ultimaker Cura, PrusaSlicer, and Onshape work effectively on Mac. Tinkercad is web-based, so it runs easily on any OS. Autodesk Fusion is out there for Mac and affords highly effective CAD and slicing in a single instrument. When you want professional-grade modeling, Blender or Rhino 3D are stable selections for Mac customers.

Q. Which 3D printing software program runs finest on lower-end computer systems?

When you’re utilizing an older or low-powered pc, Tinkercad is the very best browser-based 3D modeling instrument that requires no set up. For slicing, PrusaSlicer is light-weight and runs effectively on most techniques. Ultimaker Cura will be resource-intensive on massive fashions, however reducing preview settings and disabling real-time slicing may also help it run smoother on weaker {hardware}.

From pixels to plastic

After testing all these 3D printing software program choices, I’ve realized that there’s no one-size-fits-all resolution. Some instruments make designing fashions ridiculously straightforward, whereas others provide you with engineering-level precision. Some are good for novices, whereas others really feel like they count on you to have a level in manufacturing. However regardless of the place you might be in your 3D printing journey, there’s a instrument on my checklist that matches.

When you’re simply getting began, I’d counsel one thing easy and intuitive—no have to overwhelm your self with 100 print settings on day one. When you’re leveling up, it’s value exploring software program that offers you extra management over slicing, helps, and materials effectivity. And for those who’re already pushing the bounds of 3D printing, superior CAD software program with simulation, topology optimization, or industrial print prep is perhaps precisely what you want.

One of the best ways to determine what works is to experiment, tweak, and print. Irrespective of what number of settings I adjusted or new software program I attempted, the true studying got here from trial and error—and some failed prints alongside the way in which. So decide a instrument, begin designing, and switch these concepts into actuality, one layer at a time.

Take your designs to the subsequent dimension with the finest 3D modeling software program reviewed by my group.