Whereas unboxing a brand new shampoo tailor-made particularly for Indian hair sorts, I could not assist however marvel on the thought and precision of its creation, from the components to the packaging and even the advertising. It made me understand that bringing such a product to market isn’t straightforward. It requires cautious planning, coordination, and an environment friendly course of.

So, how do firms, particularly these dealing with complicated merchandise, handle the intricacies of growth and manufacturing? The reply lies within the finest product lifecycle administration (PLM) software program.

I found how these methods assist companies streamline product growth from ideation to launch by evaluating the highest PLM instruments. They centralize paperwork, observe progress, and allow seamless workforce collaboration, making certain each stage is meticulously managed and optimized.

Maintain studying if you wish to kickstart a product-led enterprise or enhance processes in your present product growth technique. PLM instruments may help you deliver your concepts to life extra effectively and successfully.

6 finest PLM software program: My picks for 2025

-

Siemens Teamcenter for seamless integration of product information and workflows throughout engineering and manufacturing (pricing obtainable on request)

-

Enviornment PLM & QMS for combining product lifecycle administration with high quality administration to make sure compliance (pricing obtainable on request)

-

OpenBOM for simplifying BOM administration and seamless CAD device integration within the cloud (free 14-day trial obtainable, costs beginning at $100/seat/mo)

-

Onshape for real-time cloud-based collaboration with 3D CAD and PLM options (free plan obtainable, costs for premium model beginning at $1500/seat/annum)

-

Propel for a customer-centric PLM platform built-in with Salesforce (pricing obtainable on request)

-

Duro for a easy, quick cloud-based PLM resolution tailor-made for startups and small companies (pricing obtainable on request)

* These PLM instruments are top-rated of their class, based on G2 Grid Experiences.

My prime 6 PLM software program suggestions for 2025

The very best PLM software program is designed to assist companies streamline product growth, improve cross-team collaboration, and speed up time to market. As I evaluated these instruments, I noticed firsthand how they centralize product information, enhance design workflows, and guarantee higher transparency all through all the product journey.

How did I discover and consider the most effective PLM software program?

By analyzing G2 opinions and G2’s Grid Experiences, I comprehensively understood every PLM device’s options, ease of use, and general worth. I relied on verified opinions from professionals with hands-on expertise to validate my findings.

I additionally used AI to investigate patterns in consumer suggestions, making certain I captured a variety of views on the software program’s effectiveness in streamlining product growth, enhancing collaboration, and enhancing product lifecycle administration. The screenshots featured on this article could also be a mixture of these from G2 opinions and vendor-provided visuals.

By combining G2 insights with skilled suggestions, I’ve compiled a listing of the most effective PLM software program options that can assist you select the best device to your group’s wants.

What makes PLM software program price it: My opinion

When evaluating the most effective PLM software program, I concentrate on a number of key options to find out its effectiveness for product growth groups and producers:

- Product information administration and collaboration: A robust PLM system must be a centralized hub for product data, design recordsdata, specs, Invoice of Supplies, and alter orders. I consider how simply groups can add, set up, and replace product information all through the lifecycle. I additionally assess searchability, model management, and whether or not workforce members can collaborate in actual time, offering feedback, annotations, and approvals throughout departments like engineering, manufacturing, and high quality assurance.

- Change administration and course of automation: PLM software program ought to streamline engineering change orders (ECOs) and product updates with out introducing chaos. I have a look at how simply customers can provoke, evaluate, approve, and implement modifications. The very best platforms provide visible change histories, automated approval routing, and integration with laptop aided design (CAD) and ERP methods to make sure that modifications move easily throughout the group with out lacking vital updates.

- BOM administration: Managing complicated BOMs throughout completely different product variants is a core operate of PLM. I consider whether or not the software program permits dynamic BOM creation, versioning, and straightforward comparability between variations. The best system also needs to help multi-level BOMs and integrations with manufacturing useful resource planning (MRP) methods to make sure production-ready accuracy.

- Integration with design and manufacturing instruments: A PLM resolution should combine easily with CAD, computer-aided-manufacturing (CAM), ERP, and different important methods. I consider how simply information flows between platforms with out duplication or guide entry. Good integrations decrease information silos, enhance traceability, and be certain that designs and manufacturing plans are all the time synchronized throughout departments.

- Scalability and customization: PLM software program ought to scale with companies as they develop and merchandise grow to be extra complicated. I assess whether or not the device presents customization choices like configurable workflows, dashboards, and reporting instruments. A terrific PLM system ought to permit organizations to tailor the platform to their particular product sorts, compliance necessities, and operational processes with out fixed reliance on exterior consultants.

- Compliance and high quality administration: Regulatory compliance is a giant problem for the automotive, aerospace, and medical machine industries. I assess whether or not the PLM platform contains built-in help for high quality processes (like CAPA, ISO requirements, FDA laws) and audit trails. I additionally search for documentation management, operational danger administration instruments, and digital signature help to assist groups keep compliance with minimal friction.

- Enable customers to create and handle product configurations and invoice of supplies (BOM)

- Ship options for necessities monitoring and engineering change administration

- Present a centralized repository to handle product information all through its lifecycle

- Preserve product documentation, CAD fashions, drawings, and technical specs

- Handle product prices by monitoring the prices of the elements outlined in BOMs and recipes

- Adjust to high quality requirements and laws or with customer-specific necessities

- Embody simulation options to handle product testing situations in digital environments

- Facilitate collaboration with suppliers, subcontractors, and different stakeholders

- Help producers with course of planning throughout a number of areas

- Analyze product growth KPIs and monitor engineering efficiency

This information was pulled from G2 in 2025. Some opinions have been edited for readability.

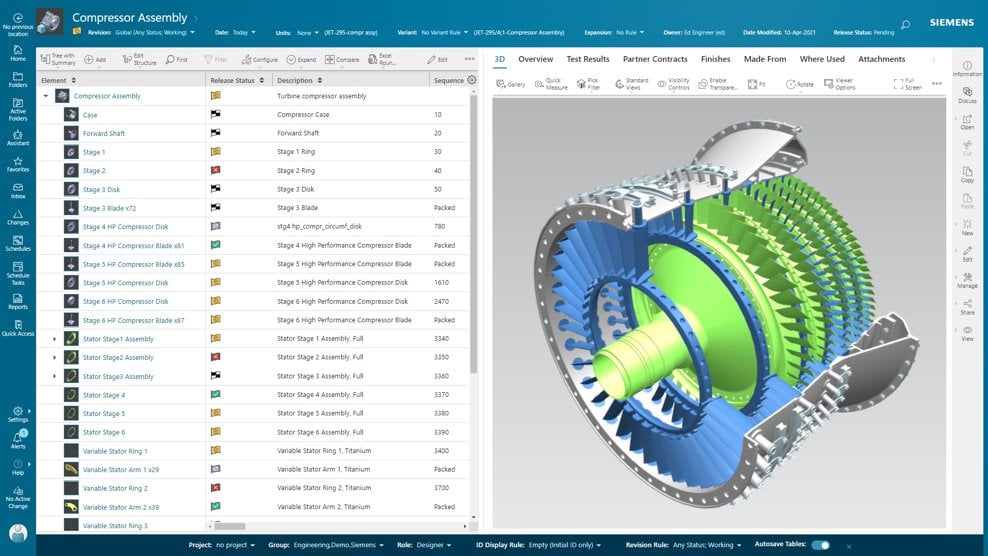

1. Siemens Teamcenter

Siemens Teamcenter stands out as a complete product lifecycle administration (PLM) resolution, particularly suited to organizations dealing with complicated product growth. Reviewers usually describe it as a dependable device for centralizing and managing product-related information, although it does have a number of usability challenges.

One characteristic I see getting a lot reward is Teamcenter’s capacity to handle, retailer, and retrieve product information. G2 reviewers continuously spotlight the way it eliminates the necessity for scattered spreadsheets and disconnected storage methods. As soon as carried out, customers say it turns into a single supply of reality that enhances information visibility and streamlines design and documentation workflows throughout groups.

There’s a lot love for the way this device handles real-time collaboration throughout departments. Many customers respect the way it allows engineering, design, and manufacturing groups to work concurrently, no matter geography. From what I’ve learn, this seamless collaboration reduces delays, prevents miscommunication, and helps quicker product growth cycles.

A generally appreciated aspect is Teamcenter’s buyer help. I’ve come throughout a number of reviewers who point out immediate, 24/7 help and useful troubleshooting help, notably in the course of the onboarding and system configuration phases. This sturdy help presence appears to assist offset among the complexity customers encounter when adopting the platform.

One other power talked about in opinions is model management and product integration monitoring. G2 customers usually notice that the platform makes monitoring revisions and product iterations straightforward over time. This visibility helps groups guarantee traceability and compliance, that are key wants for organizations with rigorous high quality assurance necessities.

That mentioned, detrimental suggestions tends to concentrate on the complexity of the platform’s implementation. Some customers are pissed off with the time and assets required to configure Teamcenter to match present workflows. It’s not simply an IT raise—a number of reviewers point out that onboarding and coaching could be steep, particularly for groups new to PLM methods.

There’s additionally noticeable dissatisfaction round efficiency points with massive datasets. Throughout a number of opinions, customers point out that Teamcenter can decelerate when dealing with excessive volumes of historic information or massive design recordsdata. Whereas it doesn’t fully cease work, it does seem to affect effectivity for groups managing data-intensive initiatives.

What I like about Siemens Teamcenter:

- I’ve seen G2 customers actually worth Teamcenter’s capacity to centralize and handle product information, making it simpler to trace and retrieve data with out counting on scattered spreadsheets.

- From what I’ve learn, customers respect how effectively it helps real-time collaboration throughout departments, serving to groups keep away from delays and work collectively effectively.

What G2 customers like about Siemens Teamcenter:

“An important characteristic I like about Teamcenter is how straightforward it’s to keep up companies, particularly with their reasonably priced pricing that delivers efficient outcomes at a low value. Additionally they provide the most effective product information and lifecycle administration options.”

– Siemens Teamcenter Assessment, Murl J.

What I dislike about Siemens Teamcenter:

- I’ve come throughout suggestions the place customers wrestle with the complexity of implementation and point out that onboarding could be time-consuming, particularly for groups new to PLM instruments.

- I’ve seen G2 reviewers continuously point out gradual efficiency when working with massive datasets or complicated design recordsdata, which impacts productiveness.

What G2 customers dislike about Siemens Teamcenter:

“When you have massive workflows, the interface could be fairly gradual in updating and displaying data. The question builder can be restricted in how complicated you may make the search standards. Since transferring to Lively Workspace, help experience appears missing, and resolving points takes longer.”

– Siemens Teamcenter Assessment, Brian H.

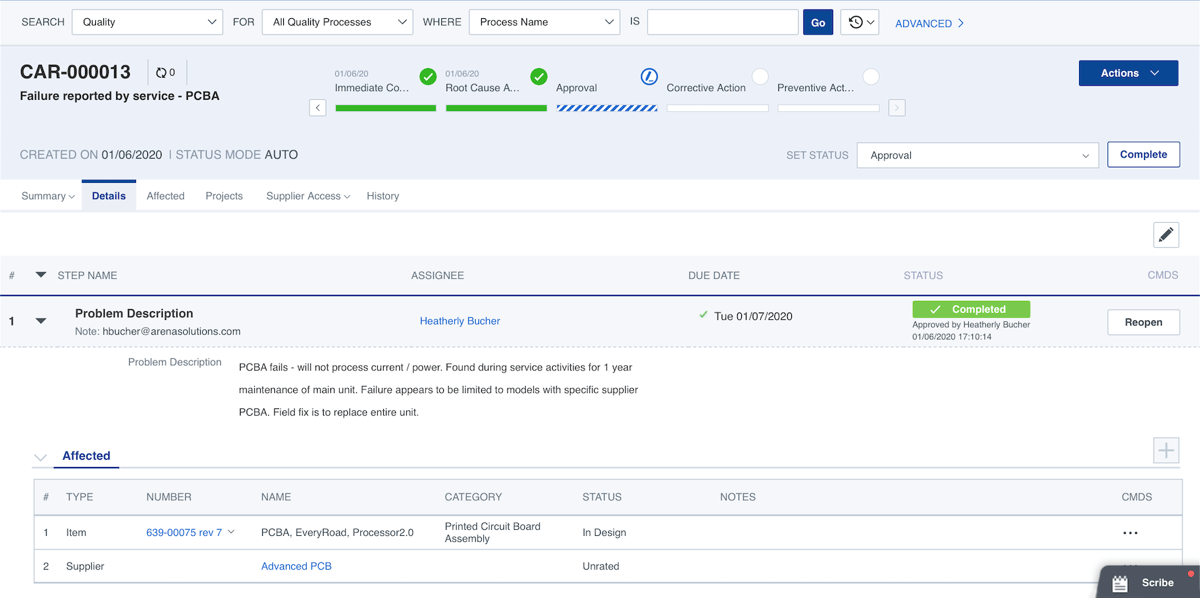

2. Enviornment PLM & QMS

Enviornment PLM & QMS is extensively considered a well-structured platform for managing product lifecycle and high quality administration processes. Customers notably respect its capacity to streamline operations throughout a number of departments, making it a sensible choice for groups seeking to combine their workflows. Nevertheless, G2 reviewers additionally point out a number of areas the place the platform might enhance when it comes to flexibility and consumer expertise.

One characteristic that I see getting a variety of reward is Enviornment’s responsive buyer help. Many G2 customers spotlight the standard of technical help, usually mentioning how rapidly the help workforce responds and the way educated they’re in resolving points. This excessive degree of service appears to ease the educational curve and assist customers successfully navigate the platform, particularly in the course of the preliminary setup section.

One thing G2 reviewers appear to essentially respect is the platform’s flexibility and customization. A number of customers emphasize how Enviornment permits them to construct workflows that match their particular enterprise wants. Whether or not it is creating approval chains or designing process flows, reviewers persistently notice how customizable the system is, making it adaptable to each compliance and operational modifications.

One standout functionality, based on customers, is Enviornment’s modular construction, which organizes workflows into completely different “worlds” akin to Requests, Objects, High quality, and Coaching. This segmentation is continuously praised by reviewers for its simplicity and readability, because it helps customers concentrate on particular duties with out feeling overwhelmed by unrelated data. Reviewers additionally respect how every “world” contains related instruments and workflows, making it straightforward to navigate and use.

One other space the place Enviornment will get excessive marks is its analytics capabilities. G2 customers usually point out how straightforward it’s to trace key metrics and create dashboards, enabling real-time undertaking monitoring. This visibility permits groups to establish bottlenecks early and make data-driven choices, maintaining initiatives on observe and groups aligned.

However, detrimental suggestions tends to concentrate on limitations round information administration. A number of reviewers point out frustration with Enviornment’s lack of ability to delete or take away gadgets as soon as they’re within the manufacturing setting. This restriction can result in a cluttered workspace over time, making it more durable to handle information effectively. Customers recommend that options like a “Trash” or non permanent holding space would enhance the consumer expertise by providing extra flexibility.

I’ve come throughout noticeable dissatisfaction round the import and multi-edit functionalities. A number of reviewers level out that whereas these options can be found, they’re usually seen as clunky and unintuitive. Importing massive information units or making use of bulk modifications tends to be extra cumbersome than anticipated, resulting in further time or workarounds with a purpose to full duties appropriately.

What I like about Enviornment PLM & QMS:

- I’ve seen G2 reviewers persistently reward Enviornment’s responsive buyer help, particularly in the course of the preliminary setup section, making the educational curve simpler to navigate.

- From what I’ve learn, customers respect the platform’s flexibility, permitting them to construct customizable workflows that swimsuit their particular enterprise wants.

What G2 customers like about Enviornment PLM & QMS:

“I believe Enviornment QMS could be a game-changer for managing high quality and compliance. It’s straightforward to make use of and helps many duties like doc management, audit administration, and real-time entry to data. The cloud-based setup retains everybody on the workforce aligned, enhancing collaboration and effectivity.”

– Enviornment PLM & QMS Assessment, Moksha M.

What I dislike about Enviornment PLM & QMS:

- I’ve seen a number of G2 customers specific frustration with Enviornment’s lack of ability to take away gadgets from the manufacturing setting, resulting in a cluttered workspace over time.

- I’ve come throughout suggestions the place customers point out that the import and multi-edit options are clunky and unintuitive, making massive information administration duties extra time-consuming.

What G2 customers dislike about Enviornment PLM & QMS:

“The interface can really feel a bit difficult for customers, with a number of tabs and circumstances. For admins, setup additionally requires deeper data of the system earlier than they will totally maximize its options.”

– Enviornment PLM & QMS Assessment, Josefine R.

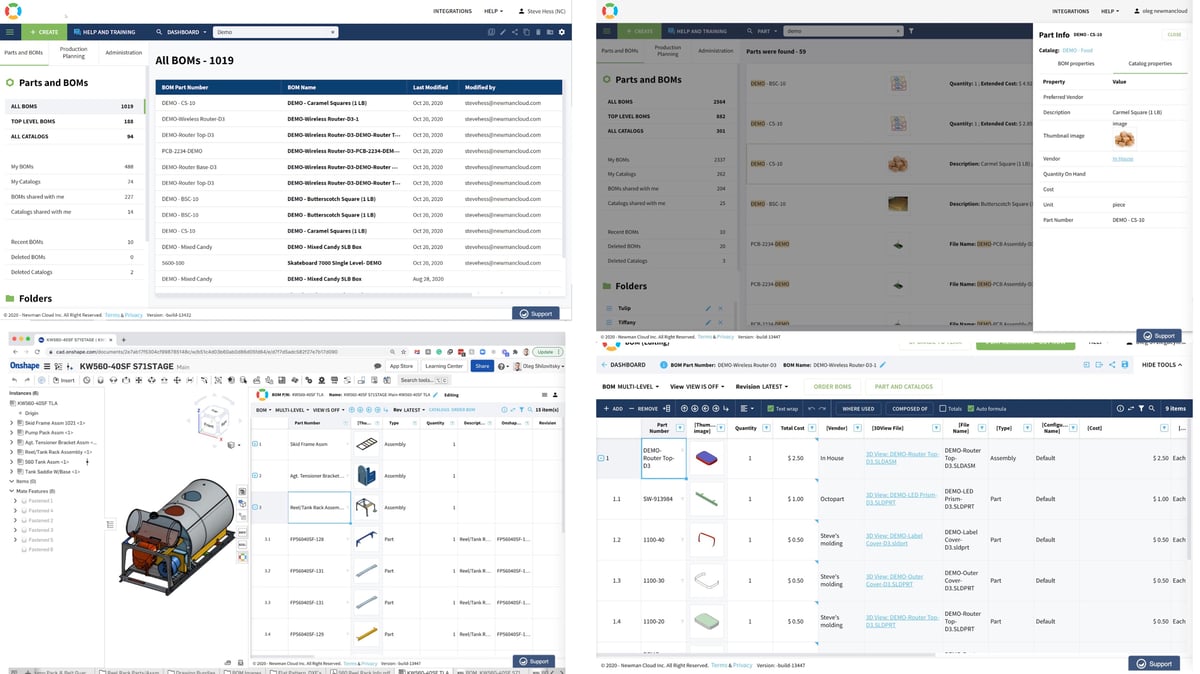

3. OpenBOM

OpenBOM is continuously praised for its ease of use and trendy design, making it particularly appropriate for small-scale operations that have to handle components, assemblies, and stock effectively. Many customers spotlight how easy and intuitive the system is, notably in the case of organizing and updating payments of supplies (BOM). G2 reviewers usually point out how rapidly they have been capable of get began with out in depth coaching, appreciating the streamlined navigation that permits them to replace half lists with minimal trouble.

A standout characteristic that I’ve seen getting frequent constructive mentions from G2 customers is the capacity to connect photographs to gadgets. This addition is extensively praised for enhancing half identification, as customers can rapidly reference photographs as a substitute of relying solely on half numbers or names. This characteristic, whereas easy, considerably enhances effectivity for a lot of customers, saving time and decreasing errors when finding particular components.

I’ve learn a number of reviewers point out how effectively OpenBOM handles primary stock administration—monitoring components, portions, and assemblies—all whereas offering a glossy, cloud-based interface. G2 customers respect the accessibility it presents, enabling groups in several areas to remain up to date in actual time. This appears notably useful for smaller companies that do not require the complexity of a full ERP system.

Nevertheless, workflow steering is an space the place I’ve seen some dissatisfaction. Many G2 customers point out frustration with the dearth of high-level workflows, notably when managing manufacturing planning and buy orders. For instance, OpenBOM mechanically fills in part portions primarily based on anticipated wants, however as a number of customers level out, this may be problematic when components arrive in incomplete shipments. The necessity to manually regulate portions and observe orders creates an inefficient and error-prone course of.

A extra vital subject highlighted by customers is efficiency with massive recordsdata, particularly throughout integration with Solidworks. A number of reviewers specific frustration with OpenBOM crashing when transferring complicated or massive meeting recordsdata, in addition to points with lacking STEP or drawing recordsdata in the course of the switch course of. These glitches can decelerate workflows and require customers to retry processes or add recordsdata manually, which detracts from the platform’s general reliability.

What I like about OpenBOM:

- I’ve seen G2 customers continuously reward OpenBOM for its ease of use and trendy design, notably how easy it’s to prepare and replace payments of supplies (BOM) with out requiring in depth coaching.

- A standout characteristic I’ve come throughout in opinions is the power to connect photographs to gadgets, which improves half identification and saves customers time by decreasing errors when finding particular components.

What G2 customers like about OpenBOM:

“OpenBOM permits my workforce to simply share recordsdata, hold them organized, and reuse them throughout a number of workforce members. It helps us handle massive workforce recordsdata so we will discover and use them when wanted. The cloud updating characteristic is very useful, letting us lock a CAD half whereas somebody is engaged on it and reopen it as soon as they’ve completed and up to date the half.”

– OpenBOM Assessment, Joshua Y.

What I dislike about OpenBOM:

- I’ve seen frustration with OpenBOM’s lack of high-level workflows, particularly round manufacturing planning and buy orders. This results in inefficient guide changes when components arrive in incomplete shipments.

- I’ve seen a number of reviewers specific dissatisfaction with OpenBOM’s efficiency when dealing with massive recordsdata, particularly throughout integration with Solidworks. The system crashes or fails to switch complicated recordsdata correctly, disrupting workflows and requiring customers to retry.

What G2 customers dislike about OpenBOM:

“Getting began was gradual, because it took my MEs a very long time to determine methods to construction their SolidWorks recordsdata to work with the OpenBOM add. We have additionally had points collaborating on the OpenBOM web site and syncing with the ME work. The excellence between gadgets and BOMs could be complicated.

– OpenBOM Assessment, Josh Okay.

Discover cutting-edge 3D modeling instruments that rework your design course of and convey your concepts to life.

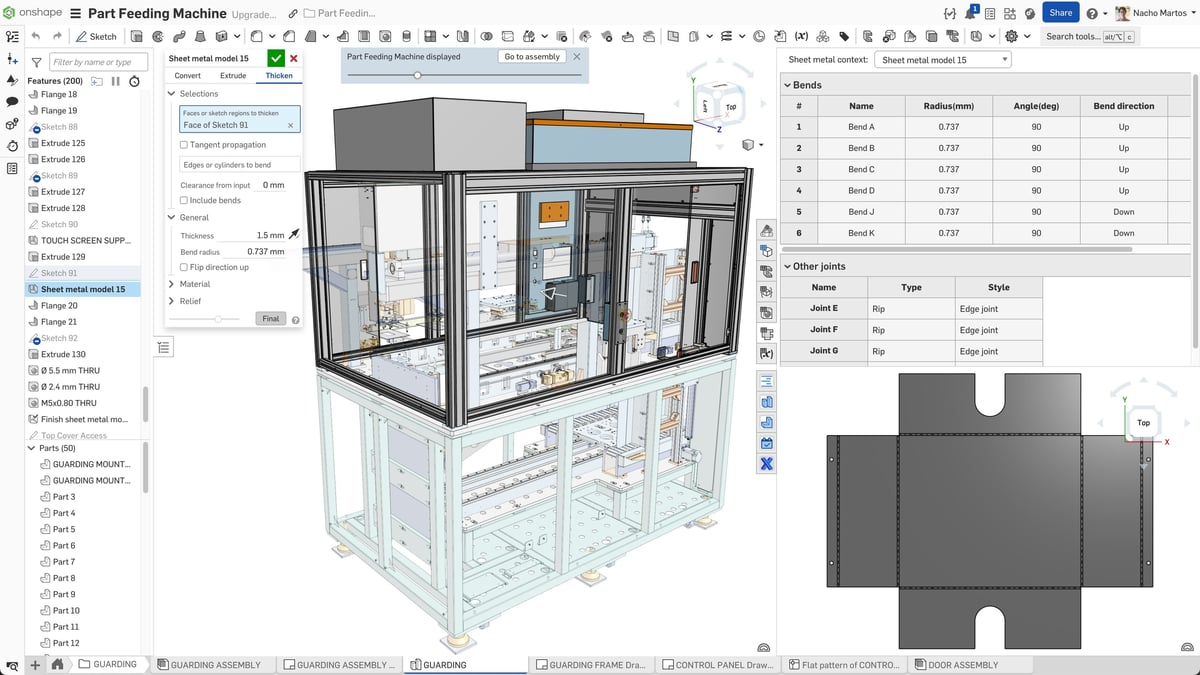

4. Onshape

Onshape is usually described as a contemporary, cloud-based CAD platform that brings many advantages, particularly for collaborative design. A typical theme in opinions is its cloud-based structure and trendy interface, which many G2 customers spotlight as a major benefit. Customers respect that it eliminates the necessity for heavy software program installations and file model conflicts, making it straightforward to entry and work on designs from wherever. The platform’s capacity to supply a collaborative setting the place groups can work in real-time is continuously praised, because it simplifies sharing and enhancing designs.

From what I’ve seen, one characteristic that persistently stands out in G2 opinions is Onshape’s built-in model and alter management system. Many customers specific appreciation for this core performance, which eliminates the necessity for separate PDM methods and guide backups. The automated monitoring of each edit, department, and merge appears to enhance collaboration, cut back errors, and improve the general consumer expertise. It additionally helps streamline product growth, particularly when built-in with Enviornment, PTC’s product lifecycle administration system.

A notable power that G2 customers often point out is Onshape’s frequent updates. Reviewers usually spotlight the platform’s fast evolution, with vital updates delivered each few weeks. Customers appear to understand that these updates usually are not simply bug fixes however usually introduce new options that enhance modeling, usability, and efficiency. This constant stream of enhancements contributes to Onshape’s status as a cutting-edge device within the CAD house.

Nevertheless, I’ve additionally seen that G2 reviewers generally point out limitations in sheet metallic modeling and documentation. In comparison with extra mature CAD platforms, some customers really feel that Onshape lacks the superior options required for dealing with complicated sheet metallic initiatives. In consequence, many customers have talked about utilizing workarounds or exporting designs to different instruments for last processing, which disrupts their workflows.

As well as, a number of G2 customers have expressed frustration with making use of partial floor particulars like labels, stickers, or logos inside assemblies. Opinions level out that there’s no easy approach to place these particulars instantly on partial surfaces. Customers usually must resort to imprints or the Render Studio, which will not be superb for fast visualizations. This limitation has left some customers wishing for extra versatile choices, particularly when engaged on shows or visible demos for stakeholders.

What I like about Onshape:

- I’ve seen that G2 customers respect Onshape’s cloud-based structure, which permits easy accessibility to designs from wherever and eliminates file model conflicts.

- Primarily based on consumer suggestions, Onshape’s built-in model management system is extensively praised for enhancing collaboration by mechanically monitoring each edit, department, and merge.

What G2 customers like about Onshape:

“It is laborious to select a favourite, however some highlights are the Git-like versioning and historical past that give final management over each transfer, the inbuilt FeatureScript language that makes creating customized options tremendous efficient, and the browser-based entry that lets me work from wherever, even an web café or my cellphone.”

– Onshape Assessment, Christopher D.

What I dislike about Onshape:

- I’ve seen customers specific frustration with Onshape’s limitations in sheet metallic modeling, usually counting on workarounds or exporting designs to different instruments for processing.

- I’ve come throughout suggestions indicating that making use of partial floor particulars like logos or stickers in assemblies is cumbersome, with no direct methodology for putting them on partial surfaces.

What G2 customers dislike about Onshape:

“The most important subject I’ve had with Onshape is the meeting construct and edit choice, which feels much less intuitive in comparison with different CAD instruments I’ve used, however I’m progressively getting it discovered.”

– Onshape Assessment, Russell W.

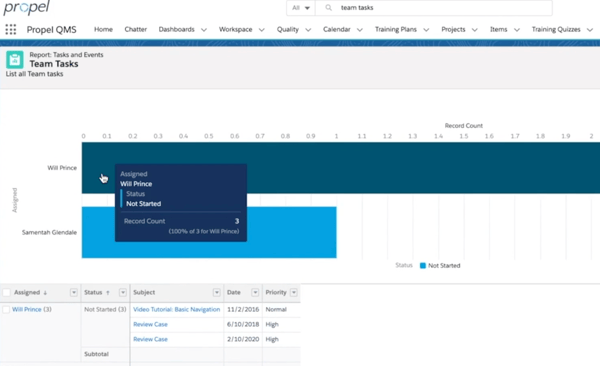

5. Propel

I’ve discovered that Propel stands out for its spectacular customization capabilities, a characteristic that many customers reward. Reviewers persistently spotlight this as a key power, noting that the platform’s capacity to be tailor-made to fulfill distinctive enterprise necessities offers it a definite edge over different options. This degree of customization permits organizations to design course of flows that align exactly with operational wants, making certain they will adapt the platform to their particular use instances with out compromising on performance.

One of many major causes customers respect Propel’s flexibility in creating workflows is the power it presents to switch processes based on enterprise wants. Customers have talked about that with the ability to tailor workflows helps groups collaborate extra effectively, designing processes which might be particular to their targets. This customization helps take away bottlenecks, optimize every day duties, and enhance general workforce collaboration, making the platform extremely efficient for streamlining operations.

Along with enhancing workforce collaboration, Propel’s adaptability is continuously cited as a major benefit in the case of boosting operational effectivity. Customers report that this excessive diploma of customization allows them to tailor their operations extra successfully, main to higher alignment with firm targets and a smoother workflow. Finally, this ends in extra organized every day operations, serving to companies meet their targets with higher ease whereas decreasing the friction that comes with utilizing extra inflexible platforms.

Nevertheless, I’ve seen that some customers on G2 specific frustration with auditability, notably round file deletions. Many reviewers point out the dearth of an audit path when recordsdata are deleted, which creates a spot in accountability. Customers, particularly these inheriting methods, have emphasised the significance of monitoring who deleted recordsdata and when, as that is vital in sustaining documentation integrity. This appears to be a recurring subject for these in industries the place detailed information are important.

One other level that comes up in opinions is e-mail notification management. Whereas Propel presents automation for sure processes, a number of G2 reviewers have famous the dearth of customization choices for e-mail notifications. Customers continuously point out that they’re unable to regulate the content material of notifications or add exterior recipients, which might result in essential updates not reaching the best folks in the best format. That is usually seen as an space that wants enchancment to reinforce communication throughout groups.

From what I’ve seen in G2 opinions, there’s additionally some suggestions concerning the platform’s studying curve. Whereas Propel is understood for its flexibility, many customers level out that it may be overwhelming for many who are new to the system. Customers want a deeper understanding of its construction to totally benefit from its customization choices, which might require vital effort and time. This steep studying curve is usually cited by customers as a barrier, notably in the case of customizing the front-end interface.

What I like about Propel:

- I’ve seen that G2 customers respect Propel’s sturdy customization capabilities, particularly the power to tailor workflows to fulfill particular enterprise wants, which boosts operational effectivity.

- Primarily based on suggestions, customers spotlight Propel’s flexibility in adapting to distinctive enterprise necessities, serving to groups obtain their targets with higher ease and enhancing collaboration.

What G2 customers like about Propel:

“I have to say that what I like about Propel is the way it makes managing the product lifecycle straightforward. When the whole lot is mapped out, we by no means lose observe of a product’s growth stage. It is a massive plus to have a device that offers us transparency throughout groups when alignment is required. The most effective components is how simply it lets us share updates and suggestions, serving to us keep away from confusion.”

– Propel Assessment, Mark P.

What I dislike about Propel:

- I’ve seen some G2 reviewers specific frustration with the dearth of an audit path for file deletions, which they really feel compromises accountability and documentation integrity.

- From what I’ve learn, a number of customers point out that Propel’s e-mail notification management is restricted, as customization choices for notification content material and exterior recipients usually are not obtainable, affecting workforce communication.

What G2 customers dislike about Propel:

“New customers would profit from full onboarding supplies as a result of the educational course of requires substantial effort. The shopper help workforce responds slowly to requests throughout occasions of excessive quantity operations, which creates frustration for customers with pressing issues. The cellular utility additionally requires higher performance together with an enhanced consumer expertise.”

– Propel Assessment, Mark H.

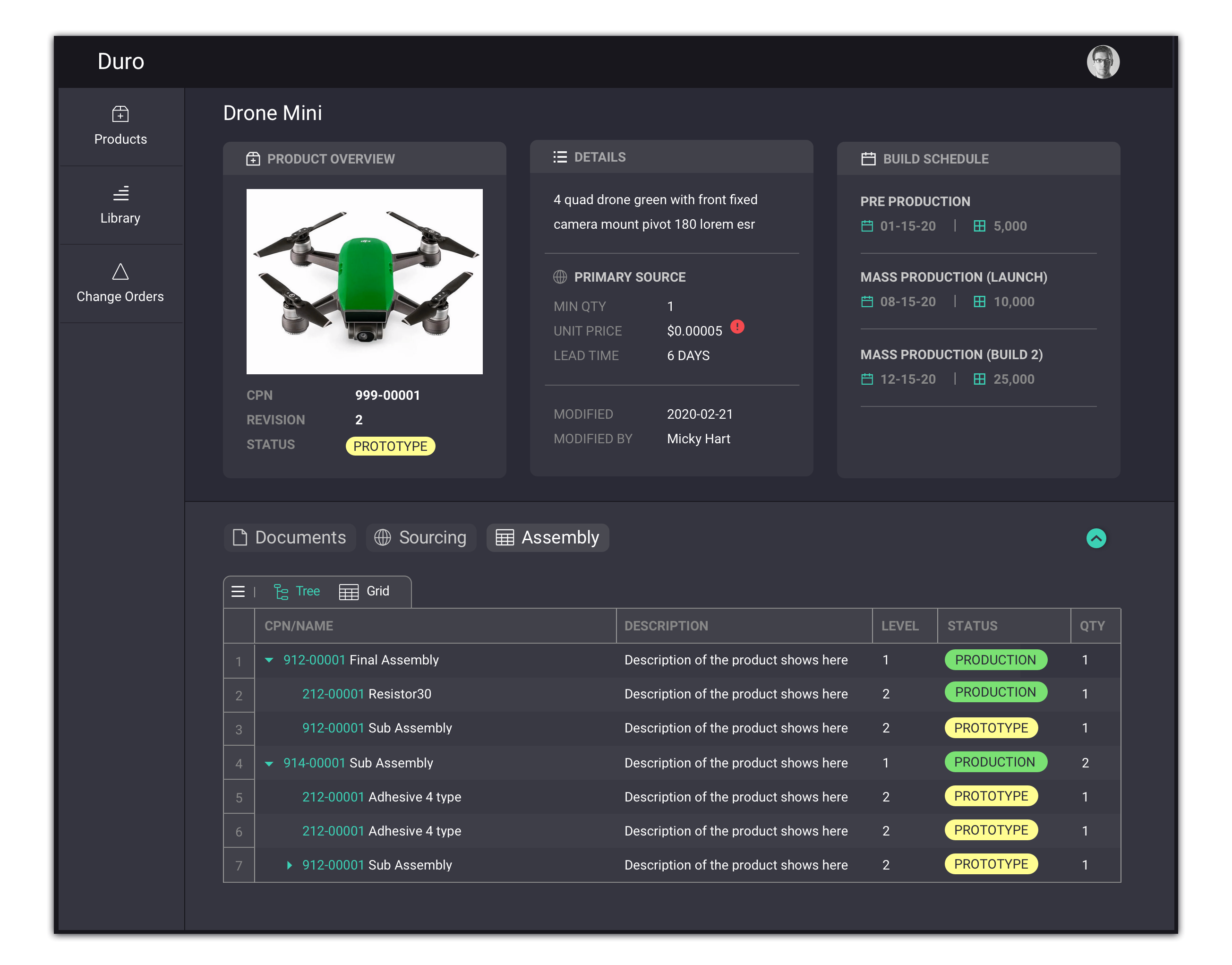

6. Duro

Duro is continuously described as a light-weight, easy-to-use PLM device that simplifies the method of scaling engineering operations. Many customers respect its user-friendly interface, which doesn’t overwhelm with pointless options. This makes it a great selection for organizations simply beginning to implement product lifecycle administration methods. G2 reviewers usually spotlight how the platform’s simplicity and ease of use make it accessible with no steep studying curve.

One characteristic that G2 reviewers appear to essentially respect is Duro’s MPN auto-match characteristic for digital engineering gadgets. Customers persistently name out this automation as a significant time-saver, notably for giant components inventories. The characteristic mechanically matches producer half numbers with corresponding gadgets within the system, decreasing guide searches and enhancing accuracy. This operate is usually praised for permitting groups to concentrate on extra strategic duties fairly than getting slowed down by repetitive information entry.

One other generally appreciated aspect, based on suggestions I gathered from G2 customers, is the integration transparency included within the enterprise plan. In contrast to many different PLM instruments that cost additional for integrations or go away customers to determine methods to join completely different software program instruments, Duro contains these integrations as a part of the plan. G2 reviewers usually point out how this transparency eliminates the effort of hidden prices or difficult integrations, making it simpler to streamline workflows throughout methods.

Nevertheless, G2 customers additionally level out some areas the place Duro might enhance. One recurring subject is the lack of forex conversion choices. Based on a number of reviewers, the platform solely helps pricing in USD, which might result in inaccuracies when managing prices for worldwide merchandise. For international organizations coping with suppliers and clients in several currencies, having the choice to transform and choose completely different currencies can be a major enchancment.

I’ve additionally seen some customers specific frustration with interface quirks, akin to materials labels being obscured regardless of obtainable web page house. Whereas not a dealbreaker, a number of G2 reviewers have talked about that this small subject brought on occasional confusion when making an attempt to entry particular materials data rapidly.

Lastly, a limitation that G2 customers usually point out is the absence of an import characteristic for vendor mechanical components. Reviewers level out that this provides guide work when getting into information for mechanical components, particularly when importing instantly from suppliers. Many recommend that having this characteristic would streamline workflows and enhance effectivity throughout completely different components classes.

What I like about Duro:

- I’ve seen G2 customers persistently spotlight Duro’s user-friendly interface and ease, making it a great selection for groups simply beginning to implement PLM methods.

- From my evaluate of G2 suggestions, the MPN auto-match characteristic for digital engineering gadgets is praised for saving time and decreasing guide information entry, enhancing general accuracy.

What G2 customers like about Duro:

“Duro has actually simplified our BOM administration. Gone are the times of spreadsheets, tedious and error-prone guide entry and updating, and confusion. Now our design engineers can concentrate on the design work and let Duro deal with the handoff of fabrication information to our provide chain workforce rapidly and pain-free!”

– Duro Assessment, Jesse G.

What I dislike about Duro:

- I’ve seen recurring suggestions in regards to the lack of forex conversion choices, which limits international organizations coping with a number of currencies.

- I’ve come throughout customers mentioning frustration with interface quirks, akin to materials labels being obscured, which might trigger confusion throughout fast entry.

What G2 customers dislike about Duro:

“Some cons embrace occasional authentication points with the Onshape plugin, and the options that may distinguish Duro as a real PLM product (versus simply PDM) don’t but appear mature sufficient to advantage their use. I might like to at some point use Duro to handle builds, part inventories, and extra—will probably be attention-grabbing to see how their product evolves sooner or later.”

– Duro Assessment, Tyler B.

PLM software program: Regularly requested questions (FAQs)

1. Which PLM software program is good for giant enterprises?

Siemens Teamcenter is widespread amongst massive enterprises for its scalability, superior integration capabilities, strong collaboration instruments, and help for complicated product buildings.

2. Which is the most effective PLM software program for small companies or startups?

OpenBOM presents reasonably priced, cloud-native PLM options designed for small to mid-sized firms. This contains important product information administration and collaboration options with out the heavy complexity.

3. Can PLM software program combine with CAD and ERP methods?

Sure. Most trendy PLM options provide seamless integration with CAD instruments like SolidWorks, AutoCAD, and CATIA, in addition to ERP methods like SAP and Oracle to make sure clean information move throughout product growth and enterprise operations.

4. What’s the distinction between PDM and PLM software program?

Product information administration (PDM) focuses primarily on managing CAD recordsdata and technical documentation, whereas product lifecycle administration (PLM) covers all the lifecycle of a product, from idea and design to manufacturing, service, and disposal.

5. Is cloud-based PLM higher than on-premises PLM?

Cloud-based PLM presents benefits like simpler updates, decrease upfront prices, quicker deployment, and accessibility from wherever. Nevertheless, some firms with strict information management wants might want on-premises options.

Precision all the way down to a ‘T’

After completely evaluating the most effective PLM software program, I’ve come to understand how a lot the best system can streamline product growth and lifecycle administration.

Every platform presents distinctive options tailor-made to completely different wants, whether or not you’re centered on collaboration throughout groups, managing complicated product information, or accelerating time-to-market. With so many choices obtainable, there’s all the time an answer that may enable you handle your product lifecycle extra effectively.

I hope my insights enable you discover the most effective PLM software program to your group—as a result of, let’s face it, managing merchandise manually simply slows innovation down!

Discover modern 3D printing options that speed up your prototyping, manufacturing, and product growth processes.